world class manufacturing pillars

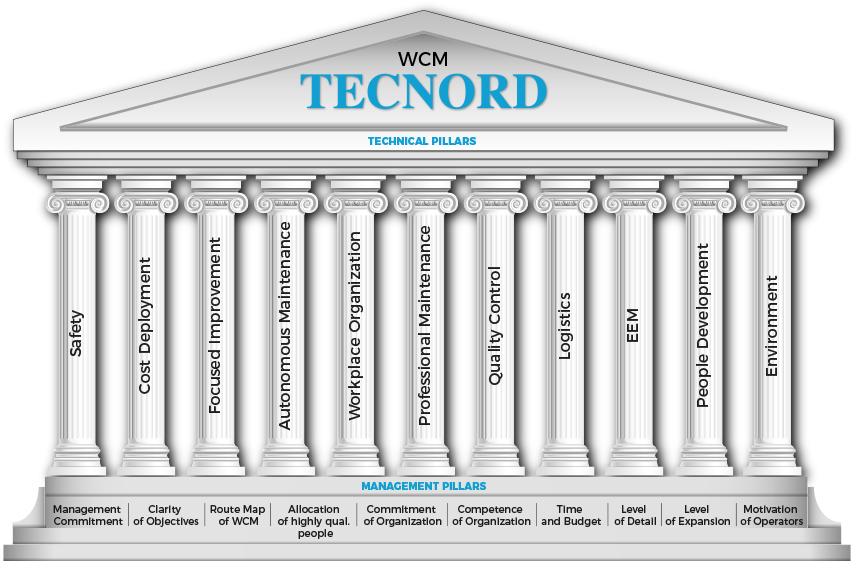

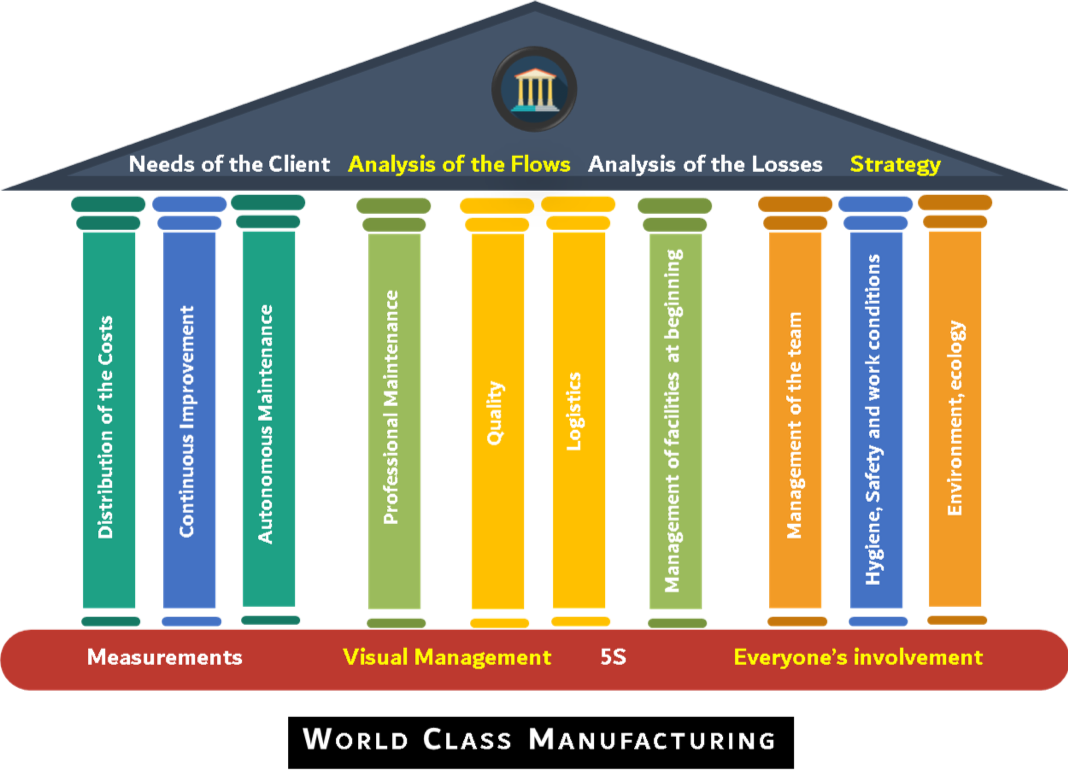

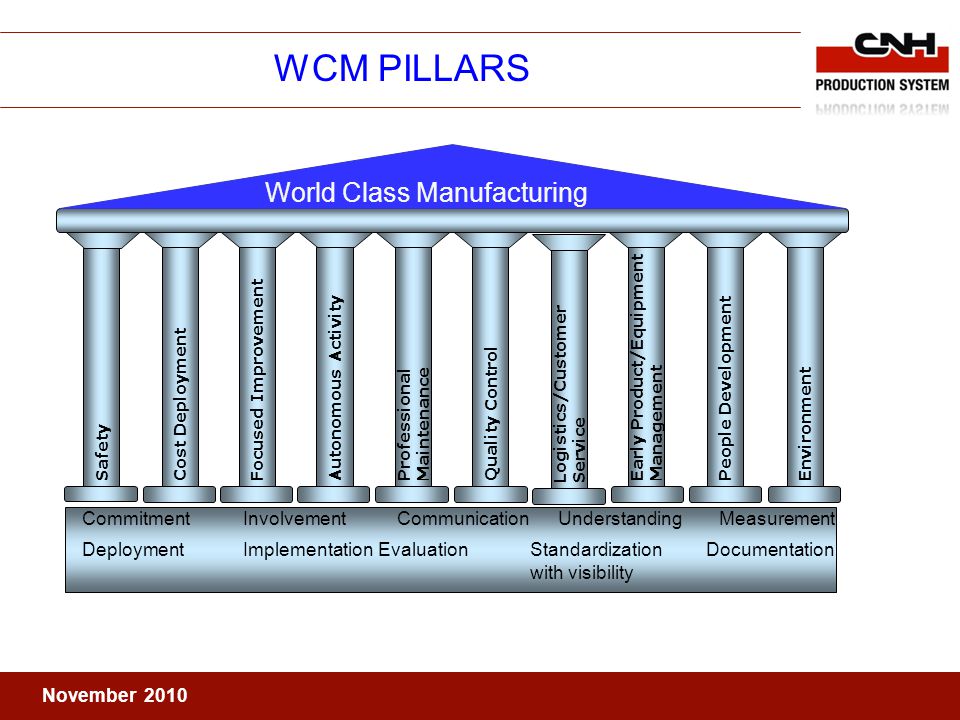

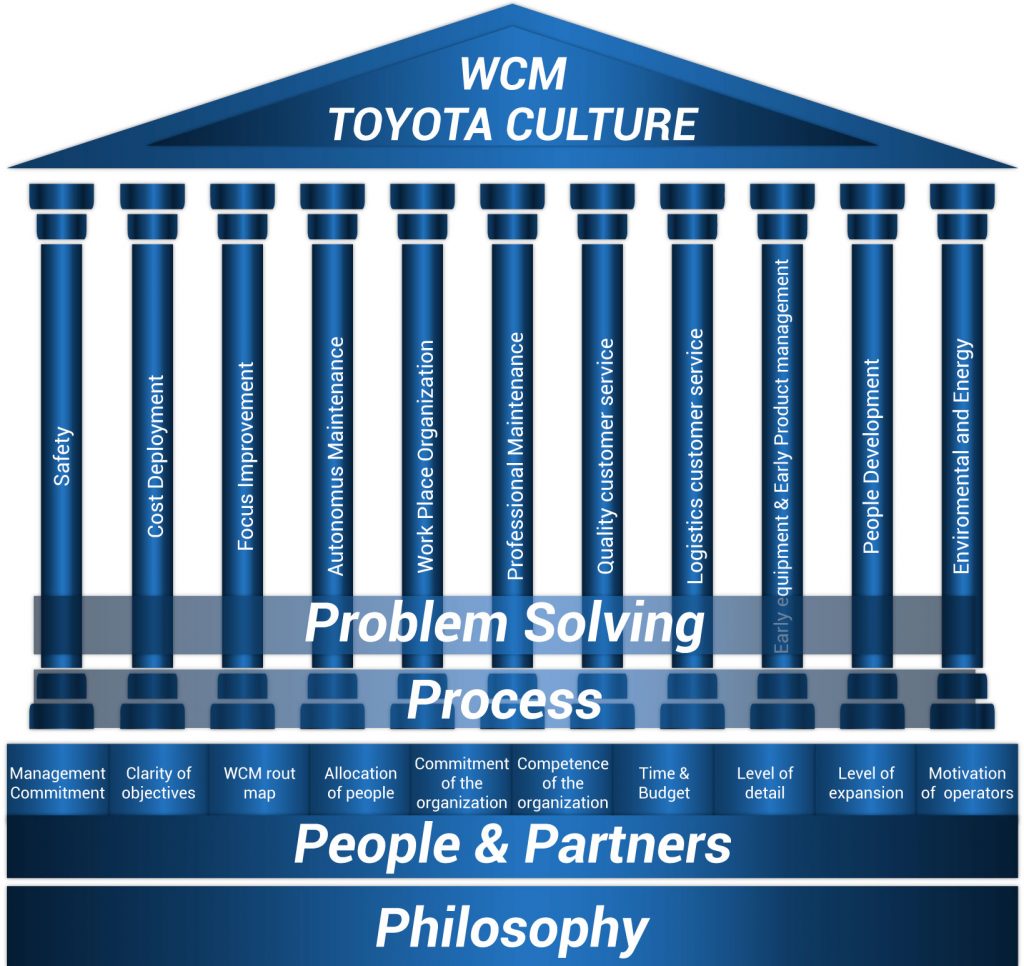

The pillars of World Class Manufacturing are specified in terms of Technical and Managerial pillars as below. WCM professionals thus have the responsibility of coordinating the design execution.

World Class Manufacturing Wcm Companies In Bangalore Seven Steps Global

The level of excellence is now expanded to all sectors of the company no longer only in strategic areas 2.

. A common definition of World Class. Silver level factory 1. The elimination of losses is.

In 2014 about 395 thousand suggestions were collected across the plants where WCM principles are applied with an average of 11 per employee. The pillars that make up the WCM Light package. The author asserts that the basic principle underlying WCM is to optimize production processes through continuous improvement and elimination of any waste.

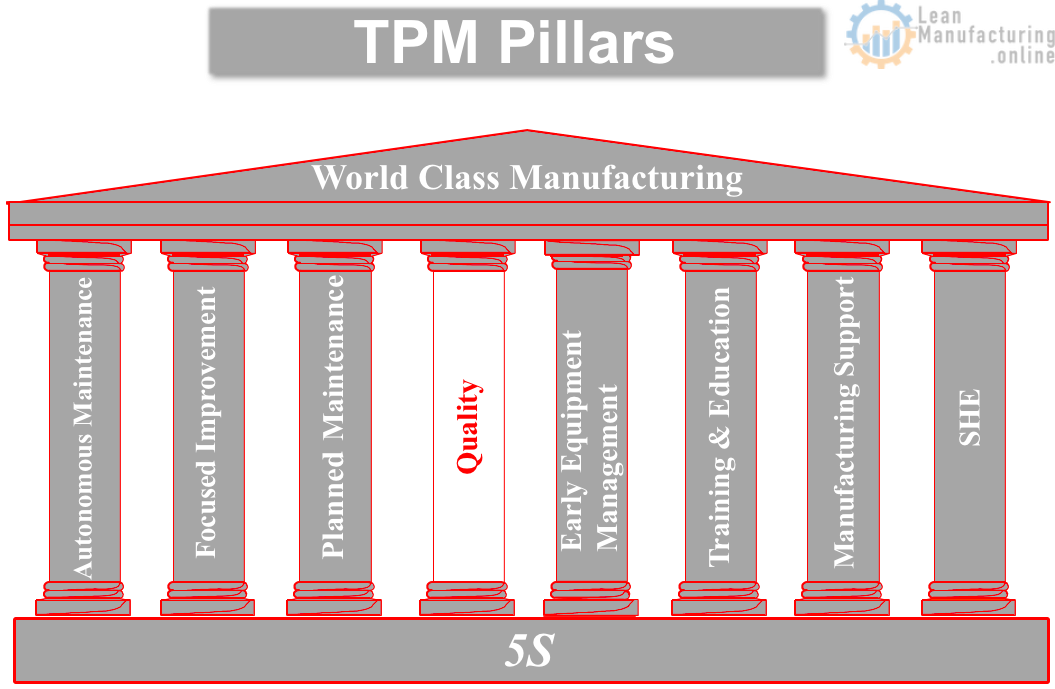

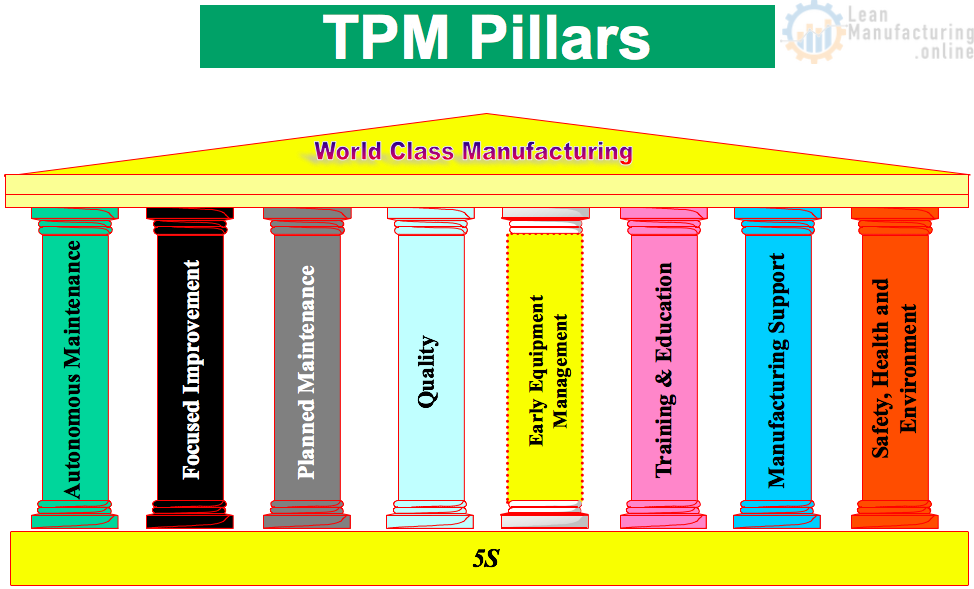

Communications Improving Performance Visibility Communication between management and the shop floor must be two-way. The concept of World Class Manufacturing is based on the positive results achieved by Japanese manufacturing companies after World War II. Developed by JIPM A System emphasizing complete Care Maintaining of machines delivered dramatic results.

The Technical pillars of World Class Manufacturing. Safety Prevent accidents embedding safe behaviour and culture in the company Cost Deployment Reduce the impact of problems from a waste. WCM is a mindset based on a continuous improvement approach 2 What is TPM.

Global quality through World Class Manufacturing. This pillar is why most manufacturing facilities fall short. Resolve problems that cause.

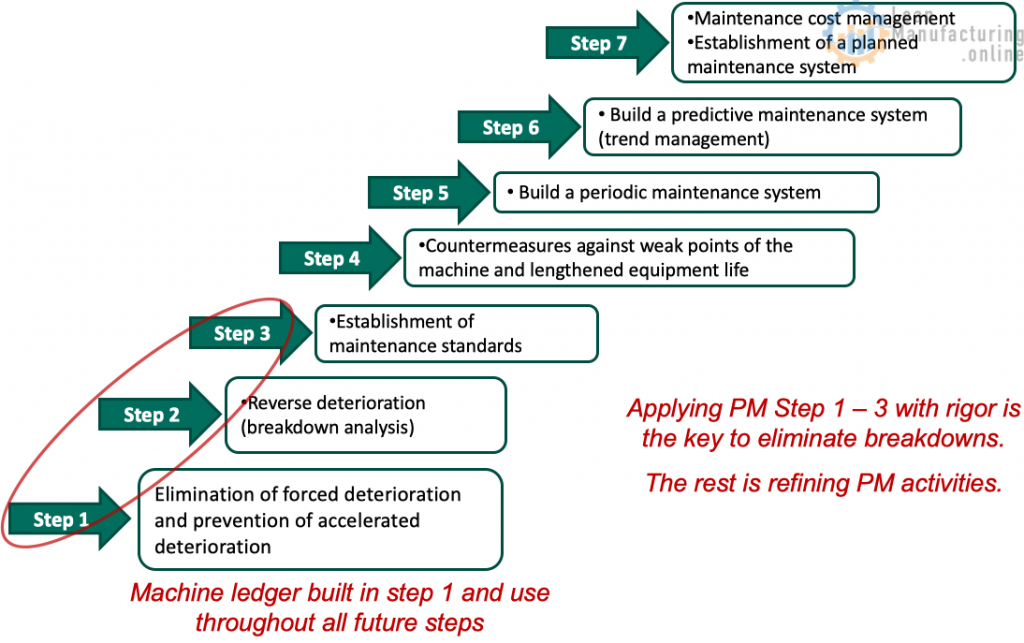

TPM WCM Zero BDs Zero Defect and Zero Accident. Achieve a level of global excellence in the area of expertise 3. The implementation and management of WCM involves continuously capturing and analysing data tracking reporting and counteracting losses and directing initiatives for continuous improvement of production processes.

Management Commitment Clarity of Objectives Route map to WCM Allocation of Highly Qualified People to Model Areas Commitment of the Organization Competence of Organization towards Improvement Time and Budget Level of Detail Level of Expansion Motivation of Operators. WCM aims to ensure that the FCA Groups facilities are flexible and competitive with the best in the world. What is World Class Manufacturing.

Recently searched Ifsi course schedule American preparatory academy west valley 2 Teacher language responsive classroom Assassination classroom karma akabane age First time buyer education course Econ course cram. The ten pillars of World Class Manufacturing. T otal P roductive M aintenance Origins.

The resulting benefits from WCM can also be viewed within the context of each pillar. 3 - Established and efficient reliability and maintenance programs. World Class Manufacturing is a set of concepts policies techniques and principles for operating and managing a manufacturing company.

Change in management of the workforce. Reliability culture is the most elusive and most important pillar to achieve World Class reliability. Sergio Marchionne CEO of Fiat Chrysler Automobiles NV.

Supporting Pillars of World Class Manufacturing A new approach to quality. World Class Manufacturing Pillars. At CNH Industrial the use of tools for sharing information and collecting suggestions is well established.

Just In Time manufacturing techniques. In 2014 14277 projects were implemented within WCM generating savings of 1956 million. Autonomous maintenance and workplace organization 5.

In fact World Class Manufacturing is a manufacturing system defined by 6 International companies including Fiat Group Automobiles with the in tent to raise their performances and standards to World Class level with the cooperation of leading European and Japanese experts and this includes all the plant processes including quality. The 10 managerial pillars of World Class Manufacturing are. The pillar of Cost Deployment represents the reporting and reduction of losses the Workplace Organization represents the improvement of.

Logistics Customer service 8. In todays global markets being agile enough to anticipate and respond to changing customer demands is essential and having the ability to adapt manufacturing techniques is not negotiable. In the management system a bronze-level company by WCM focuses only on the priority pillars for its business.

A more flexible approach to meeting customer needs.

Pillars Description And Features Open Textbooks For Hong Kong

Wcm Pillars Description And Features Business Building Information

World Class Manufacturing Or Wcm What Is It

Eight Pillars Of Total Productive Maintenance 5s Foundation World Class Manufacturing Roof Quality Continuously Improving Manufacturing

World Class Manufacturing Or Wcm What Is It

Quality Maintenance An Essential Pillar For World Class Manufacturing

Tpm Pillars Continuously Improving Manufacturing

November 2010 Wcm Pillars World Class Manufacturing Cost Deployment Autonomous Activity Professionalmaintenancequality Controllogistics Customerserviceearly Ppt Download

World Class Manufacturing Alfra Lean Advisors

World Class Manufacturing Pillars Download Scientific Diagram

Illustrates The Ten Pillars Of Wcm Download Scientific Diagram

World Class Manufacturing Pm Machine Ledger And Pm Calendar Continuously Improving Manufacturing

10 Steps To Achieve World Class Manufacturing Maintenance Practices M A N O X B L O G

The World Class Manufacturing Framework 13 Download Scientific Diagram

Road To Reliability Operational Excellence However You Define It The Foundation Is Reliability Plant Services